Bwer Company

-

Bwerpipes

largest pipes company in iraq

Welcome to BwerPipes, Iraq’s premier destination for all your piping needs. As the largest company specializing in a diverse range of piping solutions, we pride ourselves on delivering top-quality products and unmatched service.

Years of Experience

Happy Clients

Return on Investment

Conversion Boost

The Right Pipe for Every Project BwerPipes' Extensive Selection

At BwerPipes, we offer an extensive selection of piping materials including Polyethylene (PE), Unplasticized Polyvinyl Chloride (UPVC), Chlorinated Polyvinyl Chloride (CPVC), Polybutylene (PB), High-Density Polyethylene (HDPE), Polyvinyl Difluoride (PVDF), as well as a variety of traditional and specialty options such as Ductile iron pipes, Cast iron pipes, Copper pipes, PEX pipes, Steel pipes, Stainless steel pipes, Carbon steel pipes, Nickel alloy pipes, Duplex steel pipes, Concrete pipes, Fiberglass pipes, and Galvanized pipes.

Three-layer polyethylene pipes

Bwerpipes is a leading manufacturer of high-quality polyethylene hdpe Pipes in Iraq, distinguished for their superior performance and extensive benefits. Our pipes are widely favored in international projects for their versatility and reliability. With diameters ranging from 20 mm to 1600 mm and pressure classes from Pn4 to Pn32 , we offer a comprehensive range to suit diverse requirements. Each of our polyethylene HDPE Pipes undergoes rigorous manufacturing processes to meet stringent quality standards, ensuring optimal functionality and long-term durability.

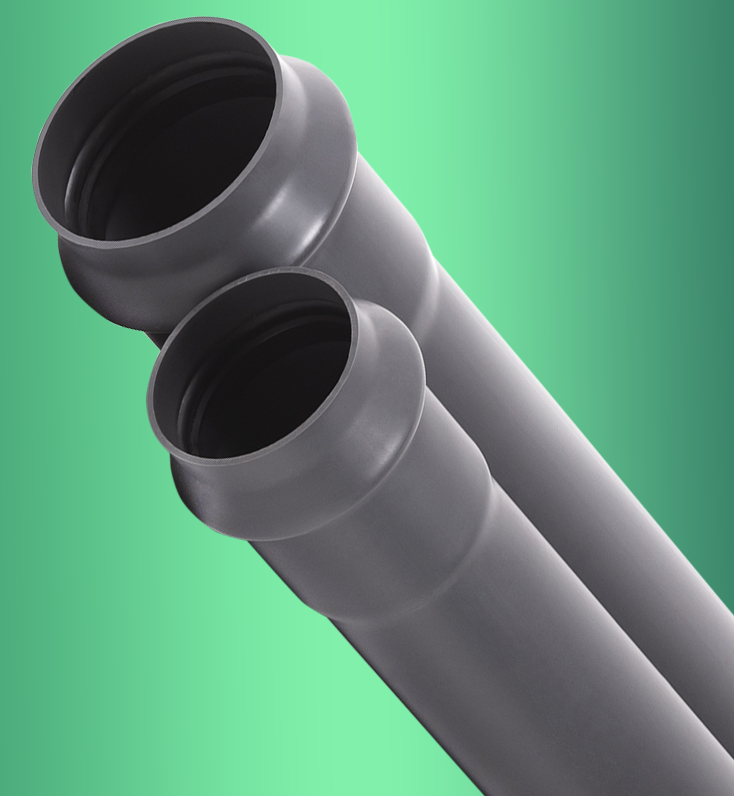

PVC-U Pressure Pipes

Bwerpipes is a leading supplier of PVC-U pressure systems in Iraq, offering a comprehensive range of products for a variety of applications. We are committed to providing our customers with high-quality piping solutions.

Comprehensiveness: We offer a wide selection of PVC-U pressure systems to meet the diverse needs of Iraqi projects.

Quality: Our pipes are manufactured using only the finest raw materials and cutting-edge technology, ensuring superior performance and durability.

Applications: Bwerpipes’ PVC-U systems are suitable for a large variety of applications in Iraq, including:Water supply Drainage Irrigation Industrial uses And more!

If you’re looking for a reliable and high-quality PVC-U pressure system for your next project in Iraq, look no further than Bwerpipes. Contact us today to learn more about our products and how we can help you achieve your goals.

High Density Polyethylene (HDPE) Coiled Pipes

Bwerpipes, a frontrunner in the Iraqi market, offers premium HDPE pipes known for their durability and adaptability and strong and flexible. These pipes are suitable for various uses, including water supply, gas distribution, irrigation, sewage treatment, and even transporting chemicals. Made from virgin PE100 material and exceeding international standards, Bwerpipes’ HDPE pipes are lightweight, environmentally friendly, safe, and hygienic. They can last for more than 50 years and resist harsh conditions. Because they are easy to install and require minimal maintenance, Bwerpipes’ HDPE pipes are a reliable and cost-effective solution for many projects.

PE Irrigation Sprinkler Pipes with Latch and Fittings

Weighbridge Solutions and Calibration Services

Bwer Company, based in Iraq, is a trusted leader in innovative weighing solutions. We offer products designed to enhance precision, efficiency, and reliability, catering to the unique needs of industries in the region. Our comprehensive range includes durable weighbridge systems, advanced load cells, precise indicators, robust junction boxes, and high-visibility remote displays, all crafted to perform seamlessly in demanding environments.

Committed to quality and tailored solutions, we support diverse industries across Iraq, from manufacturing and logistics to agriculture. Whether you need custom installations, regular maintenance, or expert calibration services, Bwer Company ensures every measurement counts with unparalleled accuracy and dependability.